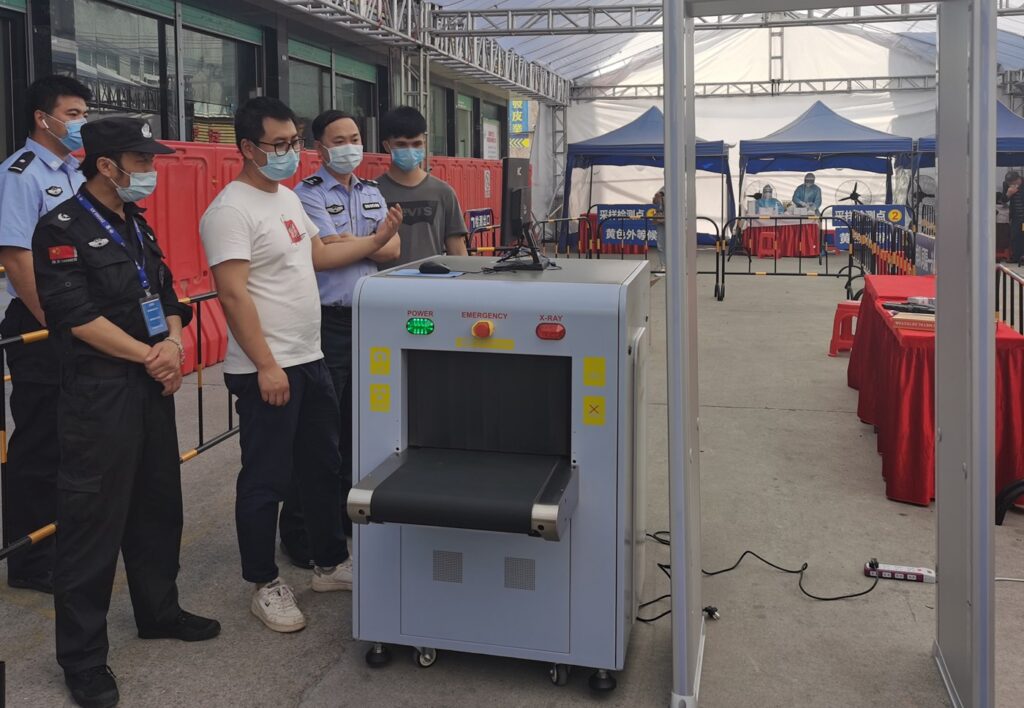

X-ray security inspection equipment is widely used, and can be seen in stations, subway stations, high-speed rail stations, airports, tourist attractions, museums, express logistics companies, and some large-scale event venues. Then what are the precautions during maintenance for X-ray security inspection equipment? What should I pay attention to when repairing? Let’s check it out today.

Precautions during maintenance of security inspection equipment

- Check the power indicator light above the entrance of the x-ray channel. When the x-ray machine is powered on, see if the yellow indicator light is on or not.

2. Check the X-ray indicator light above the entrance of the baggage inspection machine. The X-ray is emitted during operation, and see if the red indicator light is on.

3. Check the emergency stop button above the entrance of the channel, press the emergency stop button to see if it can be pressed normally, press it when the device is powered on, the device can be powered off immediately. When the button is not reset, the device cannot be performed again start.

4. Check all the keys on the keyboard and their corresponding functions. Press the zoom key, and the image can be scaled normally. Press the image processing key, and the displayed image can be transformed accordingly.

5. Check the light barrier of the channel exit and entrance. Put an opaque object on the running conveyor belt, and the rays can be turned on normally. After the equipment is powered off, wipe the lens of the light barrier and the glass installed on the channel wall with a dry silk cloth.

6. Check the electric roller can run in the predetermined direction by pressing the corresponding button. Whether the roller noise is normal and does not leak oil. If the noise is too large, it needs to be debugged and repaired.

7. Check the travel switch on the detection box and the collimator. Remove any cover plate, and the radiation can be stopped.

8. Check the deviation of the conveyor belt. See whether the conveyor belt has deviated from the motor.

9. Check the radiating vent. See whether the radiating vent is blocked, and remove the dust on it.

10. Check whether the cooling fan is working normally or not, and remove the dust on the protective net and bracket. If it can’t operate normally and can’t play the role of heat dissipation and dust removal, then it needs to be replaced or repaired. When there is a problem in the X-ray security inspection machine, if the minor problem can be solved by itself, it will be solved in time. If it is an unsolvable problem, do not disassemble the machinery and equipment privately, so as not to expand the problem, you should report it to the manufacturer and send professional technicians to repair it.

Normal maintenance work for security inspection equipment

- The equipment should be installed in a ventilated, dust-less, dry environment, avoid high temperature, humidity and direct sunlight.

- Dust the equipment first during maintenance, and use a brush and vacuum cleaner to remove the dust.

- If there is any looseness in the component or the terminal, it must be tightened immediately.

- If the components are corroded, replace them if necessary.

If any component is damaged, the reason should be found out, and the fault should be eliminated before replacing the new component. After the component is replaced, the relevant parameters must be adjusted before it can be used normally.

Do not allow foreign objects or liquids to enter the equipment during maintenance to prevent leakage or accidents.